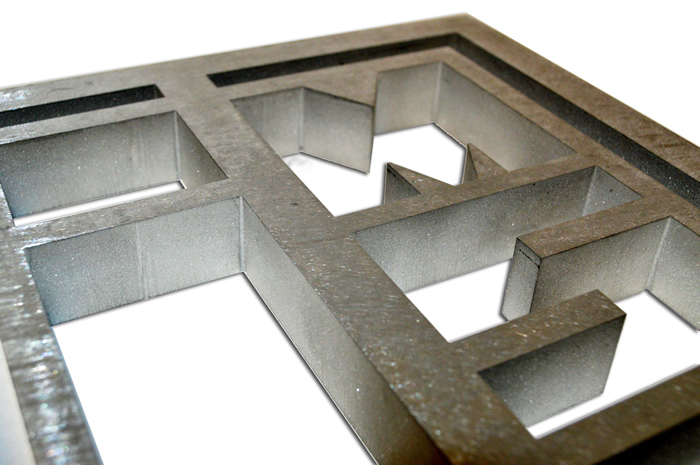

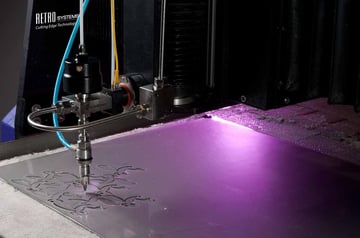

Water Jet Cutting Aluminum Plate

Dix metals inc water jet waterjet cutting video.

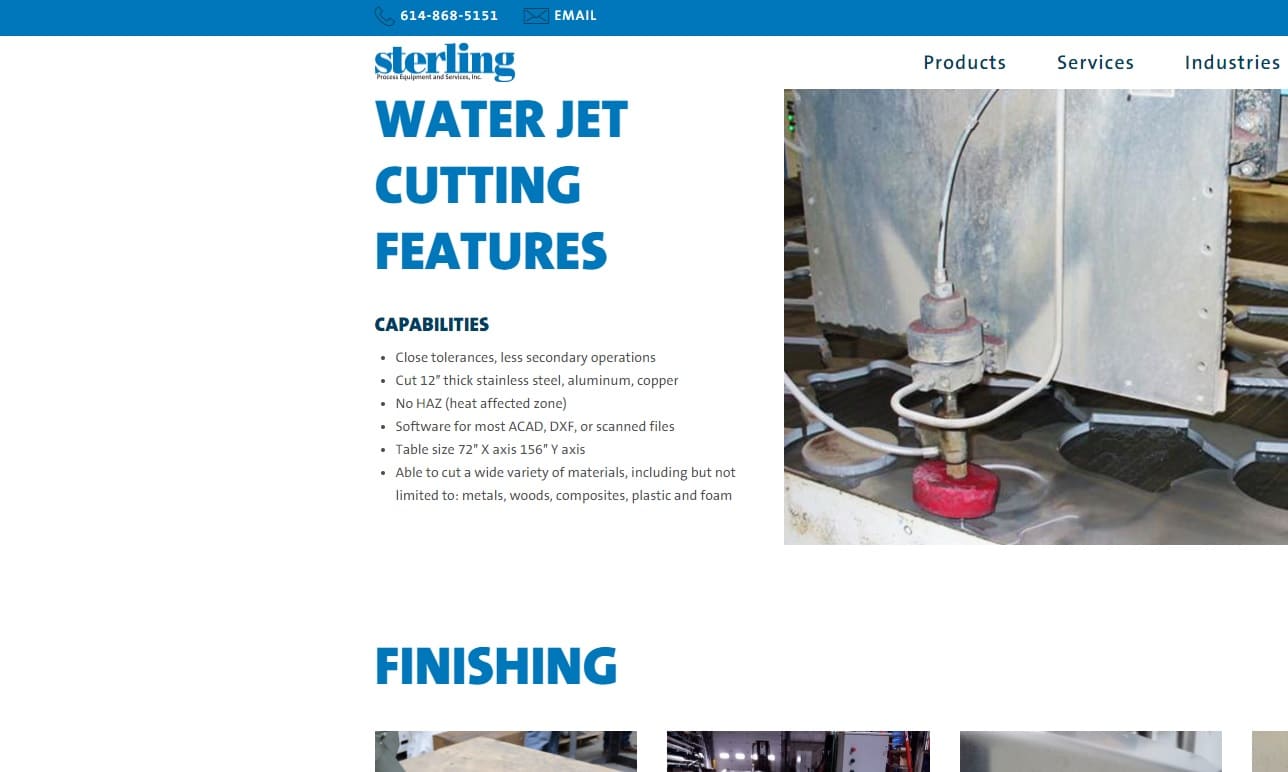

Water jet cutting aluminum plate. Application advantages of waterjet cutting. Waterjet cutting is cheaper than other processes. Sawing methods will leave jagged and sharp edges making the material useless for many purposes. Austin waterjet is a waterjet cutting sheet metal fabrication job shop serving central texas with an emphasis on steel stainless and aluminum.

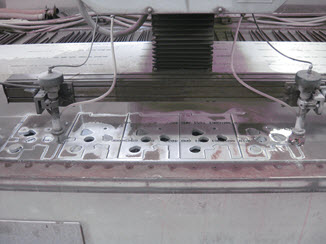

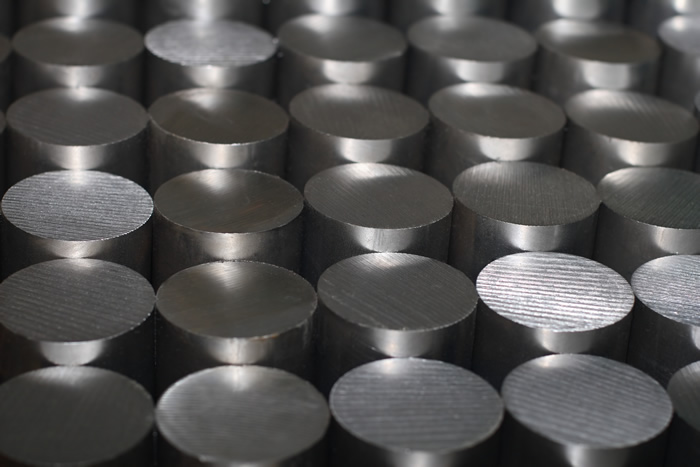

Exotics like titanium inconel hastalloy. All of our waterjet machines are equipped with multiple cutting heads that. Water jet cutting also offers many benefits when it comes to cutting aluminum that traditional industrial cutting methods are not capable of. Gummy 304 stainless most steels cut at the same speed whether hardened or not copper brass aluminum.

They are a cinch. Waterjet cutting is a great alternative to traditional plate processing. Abrasive waterjet cutting can pierce or drill holes as small as 030 in diameter 0 004 for water jet without abrasive. Waterjet cutting is most commonly used for cutting aluminum thick carbon steel and stainless steel copper brass titanium plastic and rubber.

Cuts near net shapes with no heat affected zone. Waterjet cut virtually any material. Some of the other aluminums we have processed are 5083 and 5086 7075 mic 6 cast tooling plate and all thickness of aluminum tread plate in both 3003 and 6061. Dix metals is a premier provider of 6061 aluminum plate water jet cutting blanchard grinding aluminum pl.

Aluminum stainless titanium nickel carbon alloy brass copper as well as non metal materials. A jet edge water jet cutting machine cuts 1 8 6061 aluminum. If there s an aluminum we haven t cut before we can find the right solution for your project. Water jet cutting will slice through aluminum with speed accuracy and precision.

Waterjet shape cutting for all alloys including.